WSW Technology Knowledge: Probe into the Influence of Lathe Spindle Radial Circular Runout on Machining Accuracy

Influence of pure radial circular run out of lathe spindle on machining accuracy

Abstract: This paper describes the influence of pure radial circular run out of lathe spindle on machining accuracy, including shape error and position error caused by high frequency radial circular run out.

Key words: radial; circular runout; machining accuracy

1 Preface

In some materials, such as the textbooks of colleges and universities, when analyzing the influence of pure radial circular runout of machine tool spindle on machining accuracy, it is generally assumed that the spindle axis moves in a simple harmonic straight line in the y coordinate direction (usually horizontal direction), that is, the original error h= Acosθ, θ is the spindle angle. When boring, the bore hole is elliptical, and its roundness error is the amplitude A of the radial runout of the spindle. In turning, the machined workpiece surface is close to the normal circle. Some data suggest that the pure radial runout of the spindle during turning has little effect on the roundness of the workpiece. And make simple harmonic linear motion with the principal axis h= Acosθ to illustrate. The above conclusion is valid only when the spindle runout frequency is the same as the spindle rotation times.

2 Influence of high frequency radial circular runout of spindle on shape accuracy

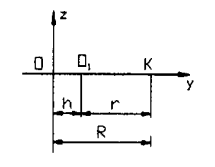

Suppose that the frequency of the radial circular runout of the spindle is twice the spindle speed, for example, if the spindle Journal of the lathe is elliptical. Similarly, let the error be h = Acos2θ. As shown in Figure 1, the distance r from the tool tip K to the average rotation axis O is a constant value. Establish a polar coordinate system fixedly connected with the workpiece, O1 is the origin, and the O1K direction in the figure is the polar axis, then the polar coordinate equation of the k-point trajectory in the workpiece coordinate system is

r = R - Acos2θ

Figure 1

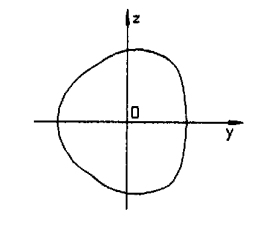

When θ= 0 and π, r = R - A. When θ= π/2 and 3π/ 2, r1= R + A. When the value θ changes between the above four values, the polar diameter r increases or decreases monotonically, that is, the machined end face is a flat circle, and its roundness error is r 1- r = 2A, which is twice the boring error described in the preface of this paper under the condition that the axis error vibration amplitude is the same. Generally, when the spindle error h= Acosθ, When n= 3, the K trajectory is cloverleaf petal shaped, as shown in Figure 2. When n= 4, it is an isocenter four leaf petal shaped symmetrical figure, and its roundness error is 2A.

Figure 2

3 Influence of high frequency radial circular runout of spindle on position accuracy

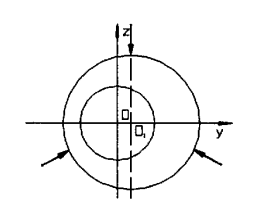

As shown in Figure 3, take the average rotation axis O of the lathe spindle as the origin to establish a spatial fixed frame. Clamp the outer circular surface of the workpiece with a fixture to process the inner hole. Take n= 1, i.e. spindle error h= Acosθ, Illustrated as θ=0. Similarly, the polar coordinate equation of the end face of the workpiece is:

r= R- A cos θ

When θ= 0, r= R- a. When θ=π, r= R + A. So O1 is not the center of the machined end face contour, and the distance between the actual contour center and O1 is A. Convert the equation into rectangular coordinates, and then translate it into a fixed spatial frame, and get:

y 2 + z 2 = R 2 + A 2 sin2θ=R2

The inner hole is approximate to the true circle, and the center of the machined inner hole is at point O, while the center of the outer circle is at point O1, that is, there is a position error A.

When n ≥ 2, the equation r = R - A cos θ. They are all central symmetrical figures with point O1 as the center. At this time, there is no position error between the outer circle and the hole, but only shape error.

Figure 3

4 Conclusion

4.1 when the lathe spindle makes pure radial circular runout in the form of simple harmonic motion in the horizontal plane, and the runout frequency is the same as the spindle rotation frequency (for example, when the spindle journal and the mating surface of the spindle and fixture have relatively large axial error), the machining wheel gallery is approximate to the true circle, but a position error of runout amplitude will be formed.

4.2 when the ratio of the main shaft runout frequency to the main shaft rotation frequency is greater than or equal to 2, there is no position error between the machined end face contour and the original contour, but there is a roundness error of twice the runout amplitude.

More about WSW Cylindrical Roller Bearing:

The roller of cylindrical roller bearing is in line contact with the raceway and has large radial bearing capacity. It is suitable for bearing heavy load and impact load. Low friction coefficient, suitable for high speed, and the limit speed is close to the deep groove ball bearing. N-type and nu type can move axially, can adapt to the change of relative position between shaft and shell caused by thermal expansion or installation error, and can be used as free end support. The inner ring or outer ring can be separated for easy installation and disassembly. The processing requirements for the shaft and seat hole are high. After the bearing is installed, the relative deviation of the axis of the inner and outer rings shall be strictly controlled to avoid contact stress concentration. Double row cylindrical roller bearing with 1:12 taper in inner hole has adjustable radial clearance and high radial stiffness, which is suitable for machine tool spindle.

WBM are professional taper roller manufacturers and suppliers in China, with bulk high-quality products in stock. If you are going to buy a customized taper roller at a competitive price, welcome to get a quotation from the WBM factory. In line with the business philosophy of pursuing excellence, continuous improvement and common prosperity, the ball header, solid steel balls, roller header produced from WBM is absolutely high-quality and inexpensive.